Rgbvisionled MIP LED: A Deep Dive into the Future of LED Display Solutions

- Time of issue:2024-9-29 9:26:27

- Views:1109

Rgbvisionled MIP LED: A Deep Dive into the Future of LED Display Solutions

- Time of issue:2024-9-29 9:26:27

- Views:1109

The LED display industry is in a perpetual state of innovation, driven by the relentless pursuit of higher resolution, greater reliability, and more efficient manufacturing. Among the latest packaging technologies making significant waves is MIP, which stands for MIP (micro in package). This technology is not merely an incremental improvement but a fundamental shift in how individual pixels are constructed and assembled, positioning itself as a pivotal solution for the next generation of fine-pitch displays.

What is MIP Technology?

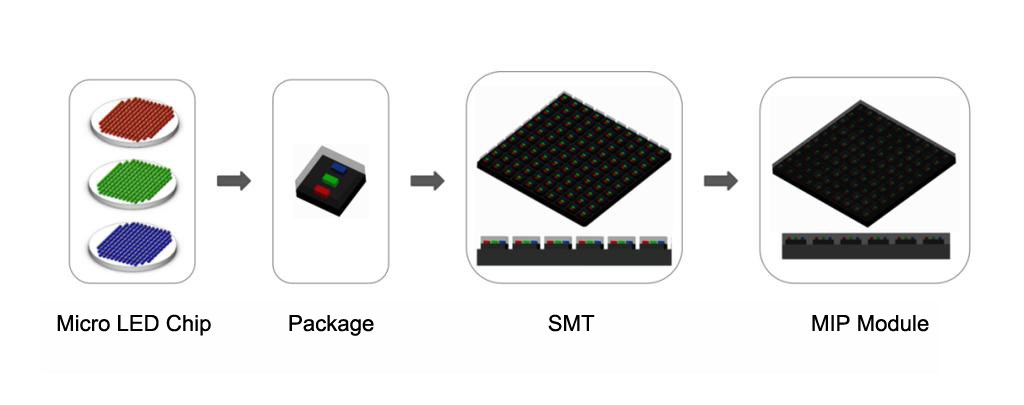

MIP is an advanced packaging technique that sits conceptually between traditional SMD (Surface-Mounted Device) and the more integrated COB (Chip on Board). In a MIP structure, the microscopic LED bare die are first packaged into individual, smaller, and standardized units. These miniature packaged devices are then surface-mounted onto a display substrate, similar to traditional SMD, but on a much finer and more precise scale.

Essentially, MIP takes the bare die and gives them a protective "suit" before they are placed onto the PCB. This hybrid approach combines the benefits of both discrete device handling and the performance of chip-level integration.

The Core Advantages of Rgbvisionled's MIP

1. Enhanced Reliability and Robustness: Unlike bare die used in COB, each MIP unit is fully packaged. This provides superior protection against moisture, dust, sulfur, and physical damage during handling, installation, and operation. It significantly improves the display's longevity and resistance to environmental factors.

2. Improved Repair Efficiency: This is one of MIP's most significant competitive advantages over COB. Defective pixels on a COB display are extremely difficult, often impossible, to repair at the factory or in the field without noticeable marks. MIP devices, being discrete components, can be individually reworked and replaced using highly precise repair stations, restoring the panel to like-new condition. This dramatically improves production yield and reduces long-term maintenance costs.

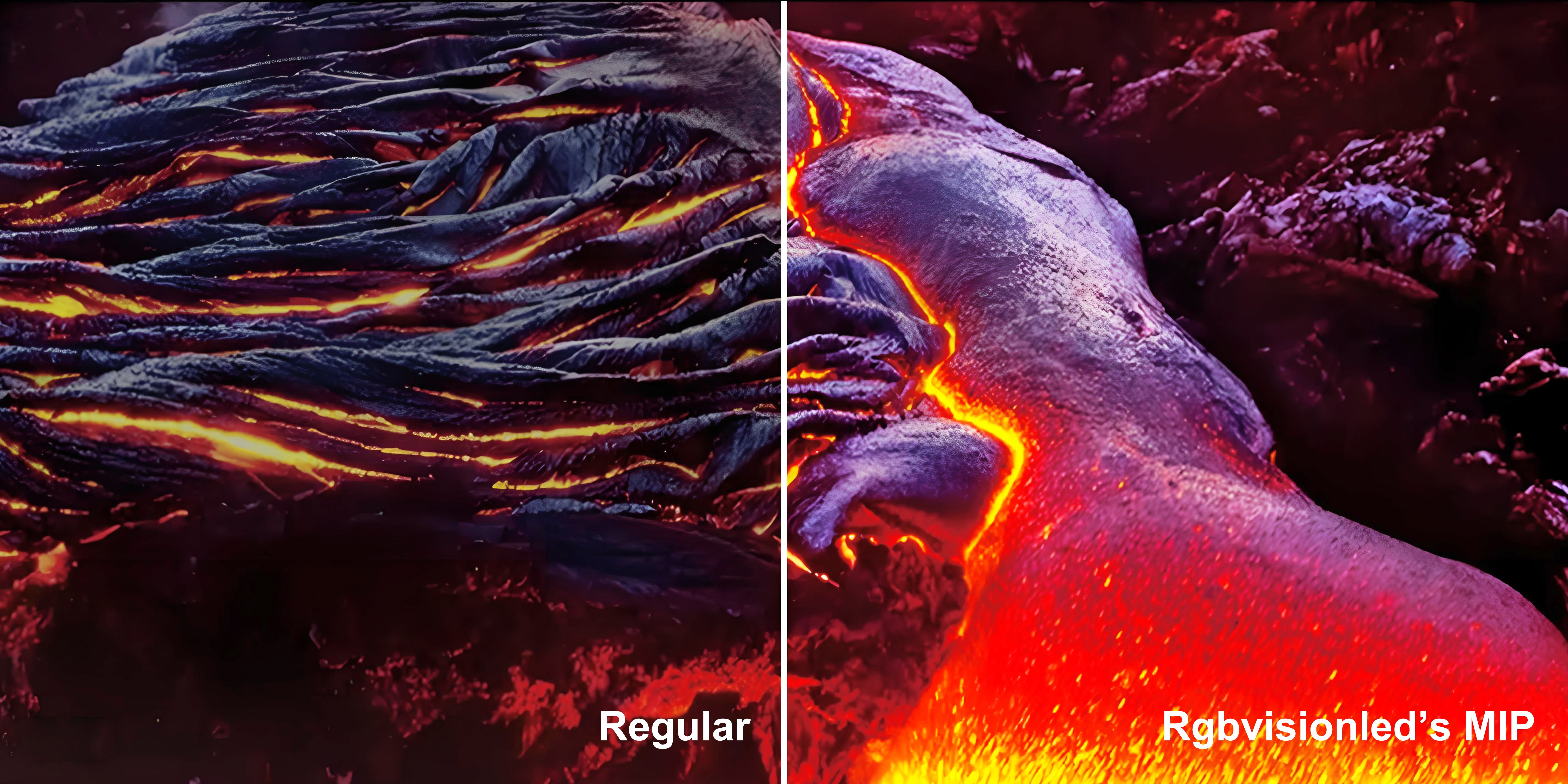

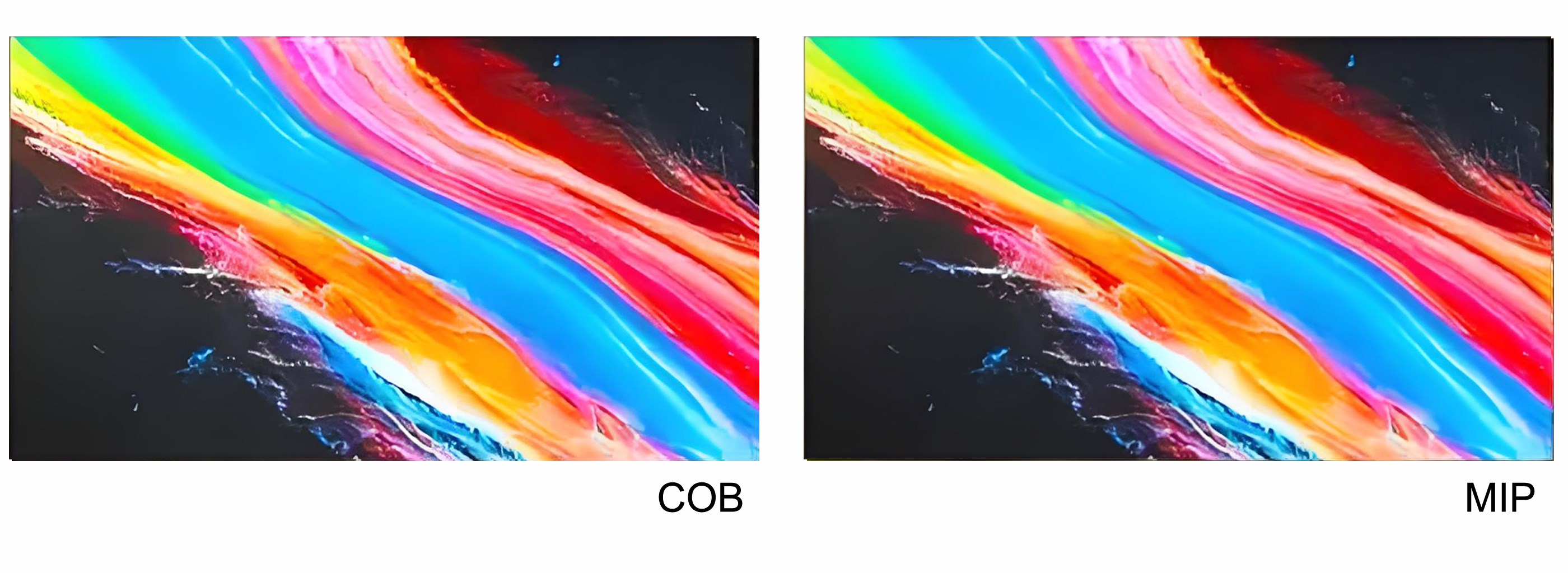

3. Superior Visual Performance: The packaged structure of MIP allows for better light control, reducing cross-talk between pixels and improving contrast ratio. The technology also facilitates better color consistency and a wider viewing angle compared to traditional SMD, especially at very fine pitches.

4. Manufacturing Scalability: MIP leverages the existing massive infrastructure and processes of the SMT (Surface-Mount Technology) industry. Manufacturers can utilize advanced, high-speed pick-and-place machines for assembly, enabling a smoother and more scalable transition to mass production of micro-LED and fine-pitch displays compared to some COB processes.

Challenges and Considerations

1. Cost Complexity: The additional packaging step adds cost to the individual pixel units. While the overall system cost may be optimized through higher yields and easier repair, the initial Bill of Materials (BOM) is a key factor.

2. Technical Maturity: As a relatively new technology, the MIP ecosystem—including standardized component specifications, specialized mounting equipment, and repair tools—is still evolving and maturing compared to the well-established SMD supply chain.

3. Pixel Pitch Limitation: While excellent for fine-pitch applications, there is a physical limit to how small the packaged MIP unit can be, potentially making it less suited for the absolute smallest pitch applications (e.g., below P0.4) where true micro-LED COB might have an edge in density.

Market Demand and Client Expectations

The market demand for MIP is rising rapidly, particularly in the high-end commercial display and control room sectors. Clients are actively seeking solutions that offer:

"Perfect Screens": End-users expect flawless image quality with zero dead pixels upon delivery and throughout the display's lifecycle. MIP's repairability directly addresses this critical demand.

Lower Total Cost of Ownership (TCO): While the initial purchase price is important, savvy clients are calculating TCO, where MIP's high yield, reliability, and easy maintenance offer compelling long-term value.

Proven Technology: Customers see MIP as a less risky evolution, building on familiar SMT principles rather than a complete process revolution.

Primary Use Cases for Rgbvisionled's MIP

MIP technology excels in applications that demand high reliability and fine pixel pitches:

Command and Control Centers: Where 24/7 operation and absolute reliability are non-negotiable.

Corporate Boardrooms & Broadcast Studios: For critical viewing environments that require impeccable image quality.

High-End Retail & Luxury Advertising: To create stunning, seamless visual experiences.

Fine-Pitch Indoor LED Walls: As a direct competitor to high-end SMD and COB in the P0.7 to P1.5 range.

MIP vs. COB: A Clear Distinction

The choice between MIP and COB is a central debate in the industry today.

Packaging: COB mounts bare die directly onto the PCB, which are then covered with a single, large protective epoxy layer. MIP mounts pre-packaged micro-devices onto the PCB.

Repairability: This is the key differentiator. COB repair is challenging and often leaves a visible scar. MIP repair is precise and can restore the pixel to its original state.

Robustness: COB's monolithic epoxy surface is very sturdy against front-impact but is vulnerable during the bare-die handling stage. MIP devices are robust from the start due to their packaging.

Process: COB requires a completely new set of manufacturing and bonding equipment. MIP can more readily adapt existing SMT lines.

Future Trends for MIP

The future of MIP is bright and points toward:

1. Miniaturization: Continued R&D will push the physical size of the MIP package smaller, enabling displays with even finer pixel pitches.

2. Standardization: The industry will move towards uniform MIP specifications, driving down costs and improving interoperability.

3. Mass Adoption in Micro-LED: MIP is widely regarded as a key enabling technology for the cost-effective mass production of consumer-grade micro-LED displays, potentially for TVs and other premium video walls.

3. Integration with Driver ICs: Future MIP packages may integrate driving circuitry directly into the package, further simplifying the PCB design and enhancing performance.

Conclusion

Rgbvisionled's MIP LED technology represents a sophisticated and pragmatic evolution in display packaging. By striking a careful balance between the high performance of integrated packaging and the practical, repairable nature of discrete components, MIP offers a compelling value proposition. It effectively addresses critical customer pain points around reliability and maintenance while providing a scalable pathway for the industry. As the technology matures and costs optimize, MIP is poised to become a dominant force in the high-end LED display market for years to come.

Stay connected via WhatsApp: +86 136 2007 8587 | Email: info@szrgbvisionled.com. to get the newest MIP technology with Rgbvisionled's team.

- Products Fine PitchRentalDOOHCommercialSportCreativeXRAcceaaories

- SolutionData VisualizationCommercial DisplayDOOH BillboardsStage RentalDigital StadiumConference RoomSecurity MonitoringXR Studio

- Showcases VisualizationCommercialConferenceDOOHStageSportXR studio

- EventsNews

- SupportTechnical SupportAfter-serviceService NetworkDownload

- About usProfileCultureTalentsContact

-

+86-136 2007 8587

-

+86-136 2007 8587

-

-

JY Building, SKW industrial park, Tangtou Community, Shiyan Town, Bao'an, Shenzhen, 518108, China.

Micro LED | COB | LED Rental Screen | LED Commercial Display | DOOH LED Billboard | Stadium LED Video Wall |

GOB | MicroLED | All-in-one Smart LED System | Creative LED

Copyright 2008-2025. SHENZHEN RGBVISIONLED TECHNOLOGY CO LTD. All rights reserved.

info@szrgbvisionled | +86 13620078587

Micro LED | COB | LED Rental Screen | LED Commercial Display | DOOH LED Billboard | Stadium LED Video Wall |

GOB | MicroLED | All-in-one Smart LED System | Creative LED

Copyright 2008-2025. SHENZHEN RGBVISIONLED TECHNOLOGY CO LTD. All rights reserved.

info@szrgbvisionled | +86 13620078587